Can you create excellence through teamwork in a consultancy environment? The best way to see if something works is to try it. So that´s what I did last year, with help of my colleagues: a pilot within the team that I was a part of at the time. Could we increase the quality of our individual assignments by applying the concepts of Cooperational Excellence? Read my in-depth case study in the White Papers section.

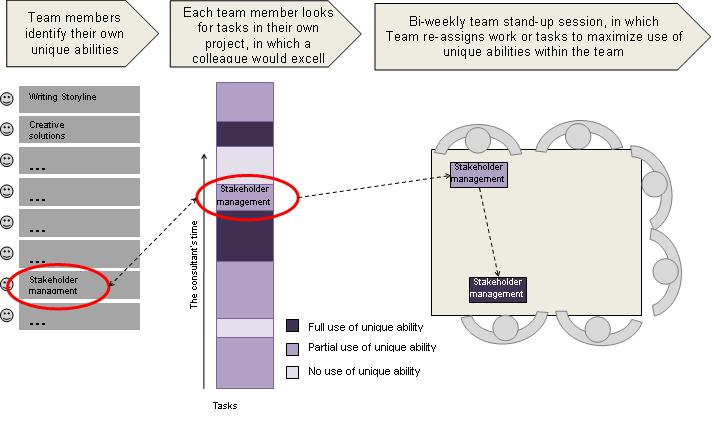

Consultants help each other, by contributing on each others projects. In a project, there may be activities that the consultant doesn’t like doing, or isn’t very good at. The solution is NOT that the consultant asks help with these activitiesIn a project, there may be activities that the consultant does an average job of – good enough, but he doesn’t excel in it. While this same activity is something that a colleague does excel in. The project will benefit if this colleague helps with this particular activityThe idea is, that every consultant has his own unique abilities – or their own activities they excel in – and the whole team will benefit if each consultant can make more use of their unique abilityWhen every consultant asks help for his/her project, based on the unique ability of the consultant he/she asks for help, the average time that each consultant uses his/her unique ability will increase

Conclusion

In those instances where it was possible to find a match between an activity and a unique ability, the pilot showed that this concept works

The difficulty lies in finding enough matches, so that everybody benefits

More details and quotes from participants can be found in my White Paper: Cooperational Excellence in Consultancy