Managing autonomous teams, or Super7 teams, requires a different management style than managing regular teams. Here’s part four of the key do’s and don’ts from my practice as a Lean Super7 consultant. This week, we’ll look into the competences that an output-manager needs. When your department introduces Super7 Operations, or other forms of autonomous teams, this may help you to adapt to the new situation you’ll face as a manager.

Do: Adapt to the new situation and experiment with the required competences

Don’t: Expect this change to be easy

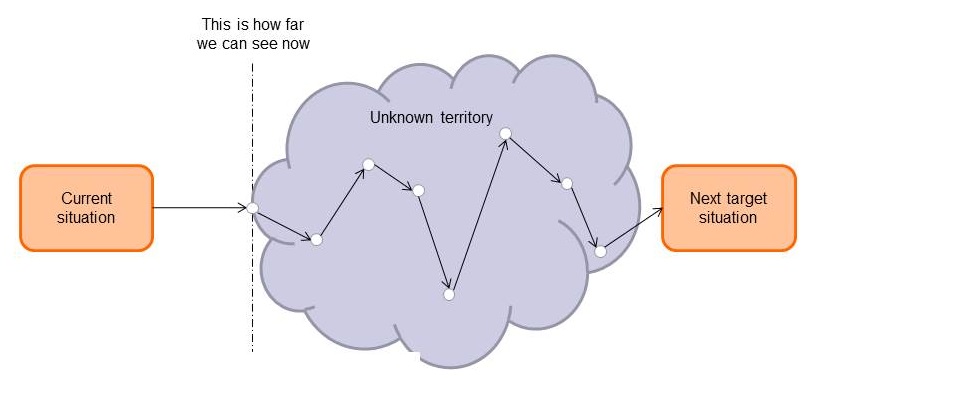

Other skills and behaviors are asked from a manager when an organization makes the transition from a classical, input steered organization towards autonomous teams or Super7’s.

Typical skills are:

• Facilitating style, focused on output

• Creativity in developing improvement experiments together with the team

• Drive to improve continuously

• Group focus instead of focus on the individuals

• Flexibility, managers should be able to manage each other’s teams

• Working fact-based, using facts and figures for planning and forecasting

• Analytical; being able to interpret data to challenge the teams and to identify improvement opportunities

Typical behaviors are:

• Proactive in finding improvement opportunities and in implementing improvements

• Focused on customers and customer processes

• Inspiring the team to be customer focused and innovative

• Helping teams and team members in their journey towards autonomy

Keep an eye out for the last post in this series: the most important tip will follow shortly

Menno R. van Dijk