Can you improve performance without operational dashboards? As a consultant, I regularly speak with team managers about their team’s improvement efforts, or the lack of thereof. One cause of stalling improvement that keeps popping up is: “I don’t have accurate data. I can’t do anything about team performance without accurate data.” Of course, performance dashboards can be important for many reasons, for one to give focus to your improvement efforts. But is the absence of performance dashboards a reason not to improve? It doesn’t have to be.

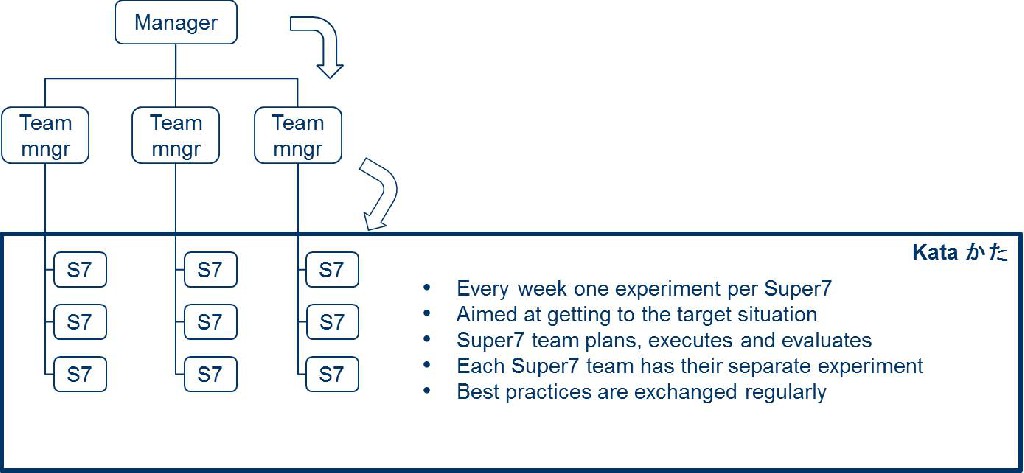

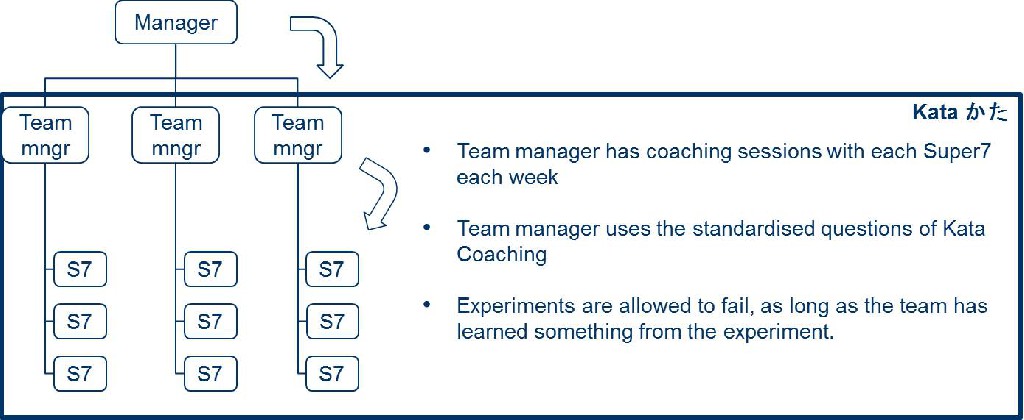

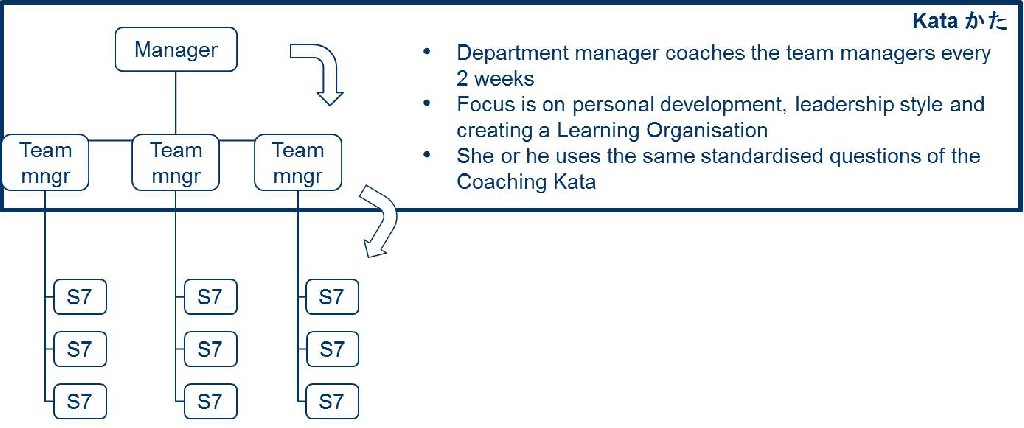

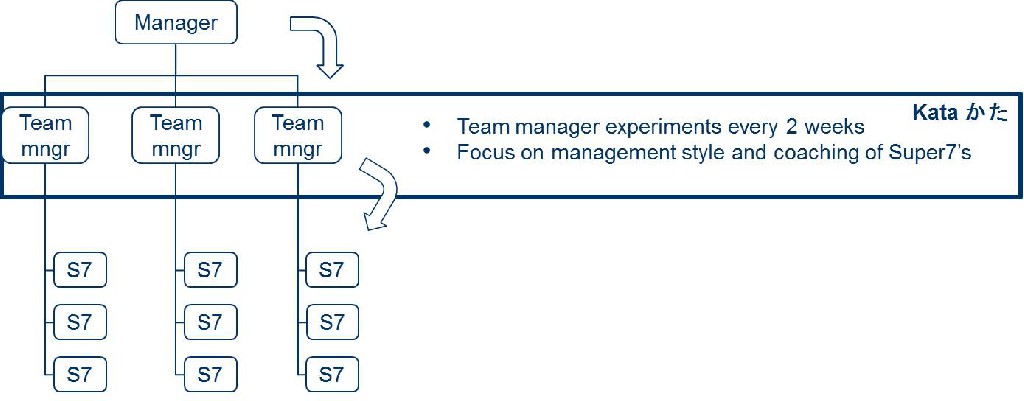

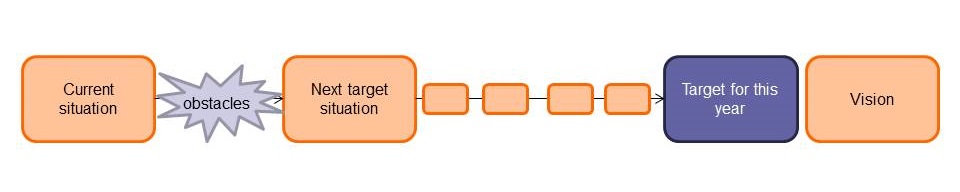

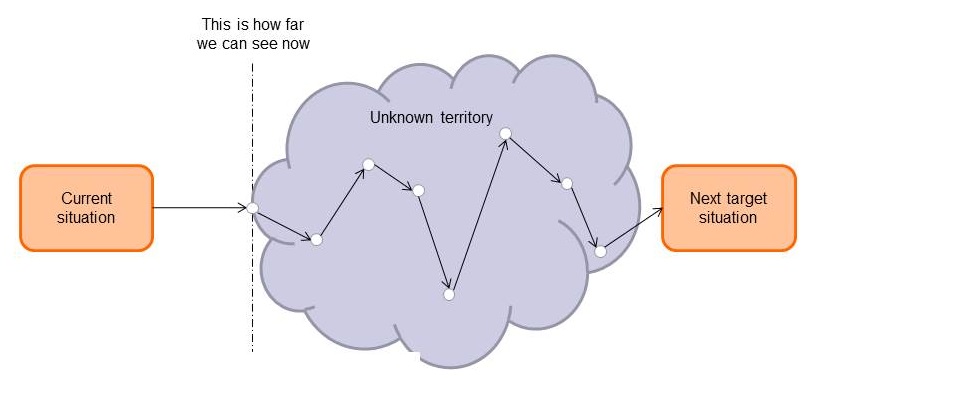

An operational team should be given the responsibility to improve their work on a daily basis. Improvement should be their habit. It should feel weird not to be experimenting at any given time. This works best with autonomous teams, which work together on one common daily goal. The Toyota Kata has taught us that these teams should do frequent, small scaled experiments. And that it is equally important that the team learns from each experiment, as that the performance actually improves.

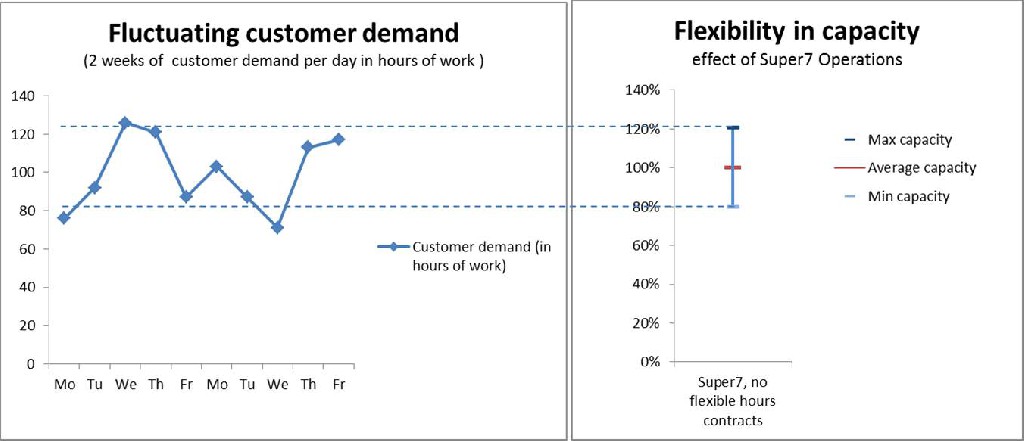

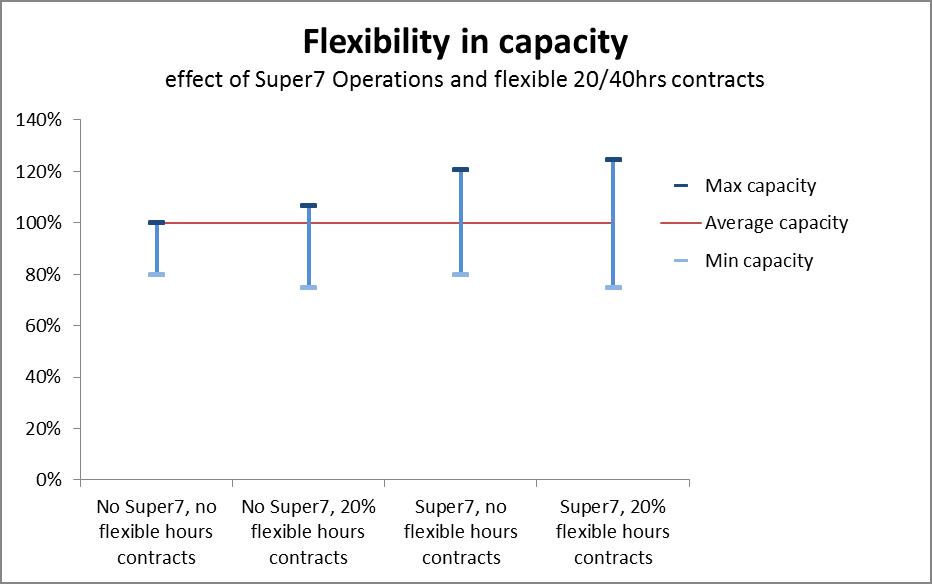

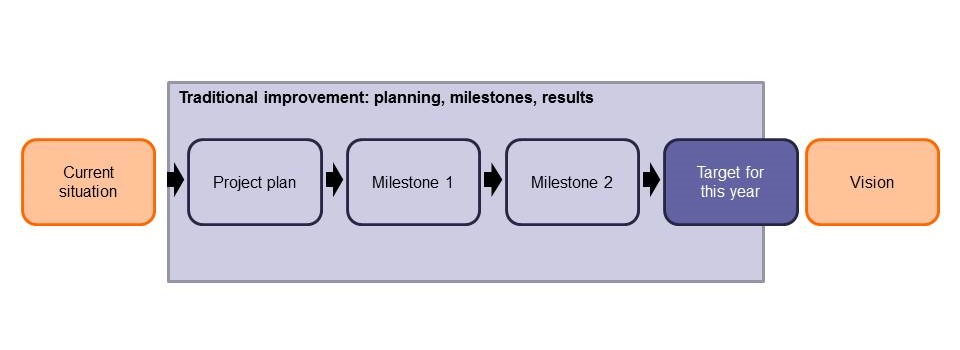

To start improving, a team needs time (a bit of overcapacity is needed to improve), and direction. The direction – what should the team’s improvement efforts focus on – could be derived from operational dashboards. But, often just as well, the direction could follow from a vision, translated into ‘target states’ (see The Toyota Kata). In Lean companies, the vision would be translated through ‘policy deployment’ or ‘hoshin kanri’ in Japanese, other companies would use for instance year-plans.

With time and direction in place, all a team needs is resourcefulness and a whiteboard. Well, you could do without a whiteboard, but in my experience it’s a great tool for improving and experimenting.

As a manager, ask your teams to start improving with what they know now. In parallel, you can work on perfecting your operational dashboards. Don’t wait for perfect dashboards. Start improving today.

Menno R. van Dijk.