In many organizations there are dashboards for everything, but there may be a better way to create accountability: through reflection and storytelling.

Last Monday, I attended a group discussion on accountability in modern organizations like Agile or Super7. Jan Smit, partner at Brooz, led the discussion on accountability in modern, less hierarchical and team-based organizations.

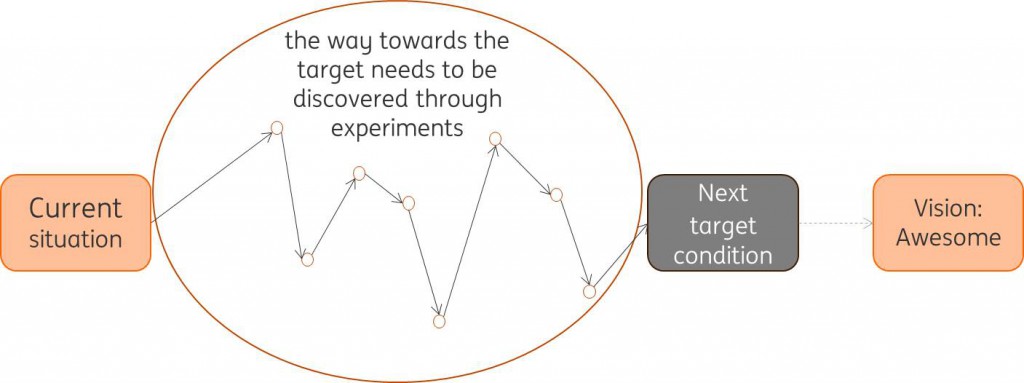

In modern organizations, Agile or Super7 for instance, the responsibility lies lower in the organization and priorities are far less static. The old ways of managing accountability with clear yearly targets, KPI’s and dashboards often hinder flexibility and agility. So, is there an alternative? Jan Smit explained that there is. Accountability can be created with far less emphasis on numbers, metrics, targets and KPI’s. According to Smit, there is a better way to go about appraisal, quality control and compliance, based on four elements:

- Reflect on what happens in practice

- Organize intervision

- Apply the critical incident method

- Use storytelling

- Listen to experiences of customers

- Gather stories from the shop floor

- Use qualitative perceptions

- Engaging in dialogue

- Gather insights and knowledge through dialogues

- Peer review, horizontal accountability between professionals

- Stakeholder meetings

- Go and see in practice

- The good-old Gemba, still the place to be for a Lean practitioner

Jan Smit relates this way of managing accountability to the Rhenish model, of Rhine Capitalism, while the target-KPI-Dashboard approach is associated with the Anglo-Saxon model of capitalism. The Anglo-Saxon model portrays an infinite faith in numbers and their objectiveness, Smit states, while numbers are at best a poor representation of reality.

In my personal experience, metrics and numbers are essential for enabling autonomous lean teams to steer themselves, to see whether they are improving and to facilitated their autonomous decision making. And, external stakeholders often demand strict numerical accountability. But still, we could surely experiment with new ways of performance appraisal, risk management and compliance in our modern organizations.

Menno R. van Dijk